McqMate

191

108.8k

190+ Design of Machine Elements Solved MCQs

These multiple-choice questions (MCQs) are designed to enhance your knowledge and understanding in the following areas: Mechanical Engineering .

| 1. |

Stressed parts are always kept in tension. |

| A. | true |

| B. | false |

| Answer» A. true | |

| Explanation: cast iron has more compressive strength. | |

| 2. |

Which process allows controlling grain structure of the product? |

| A. | casting |

| B. | forging |

| C. | none of the mentioned |

| D. | die casting |

| Answer» B. forging | |

| Explanation: in casting metal is in fluid state and hence impossible to control the grain structure. | |

| 3. |

Cast surfaces have good finishing. |

| A. | true |

| B. | false |

| Answer» B. false | |

| Explanation: cavity is surrounded by sand and hence not good finish is obtained. | |

| 4. |

In forging, metal is in which of the following stage? |

| A. | elastic |

| B. | plastic |

| C. | can be in any stage |

| D. | rigid |

| Answer» B. plastic | |

| Explanation: forging is the working of metal in plastic range. | |

| 5. |

Among casting, forging and forging which has the slowest rate of production? |

| A. | casting |

| B. | forging |

| C. | machining |

| D. | all have equal rate of production |

| Answer» C. machining | |

| Explanation: machining each part is very time consuming. | |

| 6. |

In manual assembly, cost of screw is higher than the cost of driving a screw. |

| A. | true |

| B. | false |

| Answer» B. false | |

| Explanation: generally manufacturing screw is cheaper than driving it. | |

| 7. |

Maximum carbon content in welding is usually limited to |

| A. | 0.22% |

| B. | 0.8% |

| C. | 1.5% |

| D. | 2% |

| Answer» A. 0.22% | |

| Explanation: with increase of carbon, welding becomes difficult as weld becomes susceptible to cracks. | |

| 8. |

Why tolerances are given to the parts? |

| A. | because it’s impossible to make perfect settings |

| B. | to reduce weight of the component |

| C. | to reduce cost of the assembly |

| D. | to reduce amount of material used |

| Answer» A. because it’s impossible to make perfect settings | |

| Explanation: tolerances are provided to the parts because variations in the material properties introduce errors and production machines themselves have inherent inaccuracies. another reason to introduce tolerance is that it is not possible to make perfect settings by operator so some tolerances are provided. | |

| 9. |

What is bilateral tolerance? |

| A. | total tolerance is in 1 direction only |

| B. | total tolerance is in both the directions |

| C. | may or may not be in one direction |

| D. | tolerance provided all over the component body |

| Answer» B. total tolerance is in both the directions | |

| Explanation: total tolerance is specified on both the sides of the basic dimension. this usually have + and – tolerance of equal amount. | |

| 10. |

What is mean clearance? |

| A. | maximum size of hole minus maximum size of shaft |

| B. | minimum size of hole minus minimum size of shaft |

| C. | mean size of hole minus mean size of shaft |

| D. | average of both size of shaft and hole |

| Answer» C. mean size of hole minus mean size of shaft | |

| Explanation: statistical approach allows wider tolerances compared to complete interchangeability approach. methods used by statistical approach are usually permits cheaper production. mean clearance is equal to (mean size of hole – mean size of shaft). | |

| 11. |

Which of the following is incorrect about tolerances? |

| A. | too loose tolerance results in less cost |

| B. | tolerance is a compromise between accuracy and ability |

| C. | too tight tolerance may result in excessive cost |

| D. | fit between mating components is decided by functional requirements |

| Answer» A. too loose tolerance results in less cost | |

| Explanation: loose tolerance results in increase in cost, assembly problems and poor performance of the product. tight tolerance results in unnecessary machining and inspection time. | |

| 12. |

Quality control charts doesn’t depend on which factor? |

| A. | normal distribution |

| B. | random sampling |

| C. | independence between samples |

| D. | binomial distribution |

| Answer» D. binomial distribution | |

| Explanation: in establishing of realistic specifications, control charts are considered as a good guide for the design office. quality | |

| 13. |

If a clearance fit is present between shaft and hole, what is the tolerance on shaft or hole for a complete interchangeable approach? |

| A. | ½ of maximum clearance – ½ of minimum clearance |

| B. | ¼ of maximum clearance – ¼ of minimum clearance |

| C. | maximum clearance – minimum clearance |

| D. | ¾ of maximum clearance – ¾ of minimum clearance |

| Answer» A. ½ of maximum clearance – ½ of minimum clearance | |

| Explanation: there are two approaches for deciding of tolerances and shafts i.e. statistical and complete interchangeable approach. there is no risk is taken about a single non-conforming assembly in complete interchangeable approach. | |

| 14. |

A beam is said to be of uniform strength, if |

| A. | b.m. is same throughout the beam |

| B. | shear stress is the same through the beam |

| C. | deflection is the same throughout the beam |

| D. | bending stress is the same at every section along its longitudinal axis |

| Answer» D. bending stress is the same at every section along its longitudinal axis | |

| Explanation: beam is said to be uniform strength if at every section along its longitudinal axis, the bending stress is same. | |

| 15. |

Stress in a beam due to simple bending is |

| A. | directly proportional |

| B. | inversely proportional |

| C. | curvilinearly related |

| D. | none of the mentioned |

| Answer» A. directly proportional | |

| Explanation: the stress is directly proportional to the load and here the load is in terms of bending. so the stress is directly proportional to bending. | |

| 16. |

Which stress comes when there is an eccentric load applied? |

| A. | shear stress |

| B. | bending stress |

| C. | tensile stress |

| D. | thermal stress |

| Answer» B. bending stress | |

| Explanation: when there is an eccentric load it means that the load is at some distance | |

| 17. |

On bending of a beam, which is the layer which is neither elongated nor shortened? |

| A. | axis of load |

| B. | neutral axis |

| C. | center of gravity |

| D. | none of the mentioned |

| Answer» B. neutral axis | |

| Explanation: when a beam is in bending the layer in the direction of bending will be in compression and the other will be in tension. one side of the neutral axis will be shortened and the other will be elongated. | |

| 18. |

The bending stress is |

| A. | directly proportional to the distance of layer from the neutral layer |

| B. | inversely proportional to the distance of layer from the neutral layer |

| C. | directly proportional to the neutral layer |

| D. | does not depend on the distance of layer from the neutral layer |

| Answer» A. directly proportional to the distance of layer from the neutral layer | |

| Explanation: from the bending equation m/i | |

| 19. |

Consider a 250mmx15mmx10mm steel bar which is free to expand is heated from 15C to 40C. what will be developed? |

| A. | compressive stress |

| B. | tensile stress |

| C. | shear stress |

| D. | no stress |

| Answer» D. no stress | |

| Explanation: if we resist to expand then only stress will develop. here the bar is free to expand so there will be no stress. | |

| 20. |

The safe stress for a hollow steel column which carries an axial load of 2100 kN is 125 MN/m2. if the external diameter of the column is 30cm, what will be the internal diameter? |

| A. | 25 cm |

| B. | 26.19cm |

| C. | 30.14 cm |

| D. | 27.9 cm |

| Answer» B. 26.19cm | |

| Explanation: area of the cross section of column = π/4 (0.302 – d2) m2 | |

| 21. |

Stress intensity factor is the critical value of stress at which crack extension occurs. |

| A. | true |

| B. | false |

| Answer» B. false | |

| Explanation: stress intensity specifies the stress intensity at the tip of the crack. | |

| 22. |

Fracture toughness does not depend upon geometry of the part containing crack |

| A. | true |

| B. | false |

| Answer» B. false | |

| Explanation: fracture toughness is directly proportional to a factor y that depends upon geometry of the part having crack. | |

| 23. |

How many modes are there for crack propagation? |

| A. | 2 |

| B. | 3 |

| C. | 4 |

| D. | 5 |

| Answer» B. 3 | |

| Explanation: opening, sliding and tearing are the 3 modes. | |

| 24. |

A curved beam has neutral axis is curved while loaded and straight when unloaded. |

| A. | true |

| B. | false |

| Answer» B. false | |

| Explanation: curved beam’s neutral axis is always curved irrespective of the loading. | |

| 25. |

The bending stress in a straight beam varies linearly with the distance from neural axis like that in a curved beam. |

| A. | true |

| B. | false |

| Answer» B. false | |

| Explanation: bending stress in a curved beam varies hyperbolically with the distance from neutral axis. | |

| 26. |

1816mm and radius of centroidal axis is 100mm, then find the bending stress at inner fibre whose radius is 50mm. Area of cross section of beam is 7200mm² and the beam is loaded with 100kN of load. |

| A. | 97.3 |

| B. | 95.8 |

| C. | 100.6 |

| D. | none of the mentioned |

| Answer» C. 100.6 | |

| Explanation: e=100-89.816=10.8184mm, h=89.1816-50=39.1816mm, m=100 x 100 n- | |

| 27. |

1816/ [7200 x 10.8184 x 50] or σ=100.6N/mm². |

| A. | 14.80mm |

| B. | 13.95mm |

| C. | 16.5mm |

| D. | 17.2mm |

| Answer» B. 13.95mm | |

| Explanation: σ(b)=mh/ aer or σ(b)=1000x4dx(4d-0.2d-3.5d)/ 0.8d²x0.02dx3.5d , σ(b)=21428.6/d² | |

| 28. |

A curved beam with eccentricity 0.02D is loaded with 1kN.Centroidal radius=4D and inner and outer radii are 3.5D and 4.5D respectively. Area of cross section is 0.8D². Find the dimension D if allowable stress is 110N/mm² and considering only direct tensile stress. |

| A. | 4.7mm |

| B. | 6.8mm |

| C. | 13.95mm |

| D. | 3.4mm |

| Answer» D. 3.4mm | |

| Explanation: direct tensile stress=1000/0.8d² or σ (t) =1250/d² 1250/d²=110 or d=3.4mm. | |

| 29. |

All type of stresses vanishes after as soon as the applied load is removed. |

| A. | true |

| B. | false |

| Answer» B. false | |

| Explanation: residual stresses are independent of the load. | |

| 30. |

Residual stresses are always added in the load stresses and hence are always harmful. |

| A. | true |

| B. | false |

| Answer» B. false | |

| Explanation: residual stresses may be beneficial when they are opposite to load stresses and hence are subtracted from load stresses. | |

| 31. |

Which of the following is the numerator of factor safety formula? |

| A. | working stress |

| B. | shear stress |

| C. | tensile stress |

| D. | ultimate stress |

| Answer» D. ultimate stress | |

| Explanation: factor of safety is defined as ratio of ultimate stress and working stress. it is also called as factor of ignorance. the factor of safety is dependent on the type of load. | |

| 32. |

Which of the following can be the factor of safety for shock loading? |

| A. | 11 |

| B. | 13 |

| C. | 4 |

| D. | 7 |

| Answer» B. 13 | |

| Explanation: for shock loading, the range in which the factor of safety can lie is 12 to 15. therefore only 13 lies in that range and 11, 4, 7 are all values which are beyond that range. | |

| 33. |

Factor of safety is used to find out the reliability of the design. |

| A. | true |

| B. | false |

| Answer» A. true | |

| Explanation: factor of safety tells us about how much load the material can take before it fails. basically, it states the load carrying capacity of a material beyond the actual load. | |

| 34. |

What can understand by the factor of safety equal to one? |

| A. | it means that the structure will fail under load |

| B. | it means that the structure will only support the actual load |

| C. | it means that the structure will support more than the actual load |

| D. | there is no relation between factor safety and load application |

| Answer» B. it means that the structure will only support the actual load | |

| Explanation: when the factor of safety is one it means that the ultimate stress is equal to the working stress and therefore the body can only support load up to actual load and no more before failing. | |

| 35. |

For which of the following design factor of |

| A. | 0.1 |

| B. | 1 |

| C. | 2 |

| D. | 0.9 |

| Answer» C. 2 | |

| Explanation: if the design factor of safety is not more than 1 then the design may not work and will fail under certain conditions. | |

| 36. |

What is a safe factor of failure for a component which on failure can result in financial loss or serious injury? |

| A. | 1 |

| B. | 2 |

| C. | 3 |

| D. | 4 |

| Answer» D. 4 | |

| Explanation: for components which on failing can be hazardous and can lead to serious injuries, death and financial loss, the factor of safety should be taken equal to or more than 4. | |

| 37. |

Design factor for most aircraft structures is 2. |

| A. | true |

| B. | false |

| Answer» B. false | |

| Explanation: the design factor of safety for most aircraft structures or components is taken to be 1.5 and not 2. more factors affect this value, but it is most of the time taken as 1.5. | |

| 38. |

Does ASME Standard take into consideration shock and fatigue factors? |

| A. | yes |

| B. | no |

| Answer» A. yes | |

| Explanation: moment is multiplied by a number to consider these factors while designing the shaft. | |

| 39. |

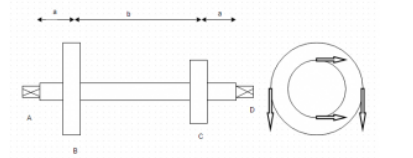

Calculate the tension in the rope of pulley C.

|

| A. | 6778.3n and 7765.3n |

| B. | 5948.15n and 2288.75n |

| C. | 5468.4n ad 8678.3n |

| D. | none of the listed |

| Answer» B. 5948.15n and 2288.75n | |

| Explanation: (p₃-p₄)x150=549.3×1000 and p₃/p₄=2.6. hence p₃=5948.15n and p₄=2288.75n. | |

| 40. |

If bending moment on point B in horizontal plate is M and in vertical plane is m, then the net bending moment at point B is?

|

| A. | m |

| B. | m |

| C. | m+m |

| D. | √m²+m² |

| Answer» D. √m²+m² | |

| Explanation: the two moments act perpendicularly to each other. | |

| 41. |

If yielding strength=400N/mm², the find the permissible shear stress according to ASME standards. |

| A. | 72 n/mm² |

| B. | 76 n/mm² |

| C. | 268 n/mm² |

| D. | 422 n/mm² |

| Answer» A. 72 n/mm² | |

| Explanation: 0.18×400. | |

| 42. |

The strength of hollow shaft is more than the strength of solid shaft of same weight. |

| A. | true |

| B. | false |

| Answer» A. true | |

| Explanation: outer fibers are more effective in resisting the applied moments. in hollow shafts material is removed and spread on a larger radius. | |

| 43. |

Solid shafts are used in epicyclic gearboxes. |

| A. | true |

| B. | false |

| Answer» B. false | |

| Explanation: in epicyclic gears, one shaft rotates inside other and hence hollow shafts are used. | |

| 44. |

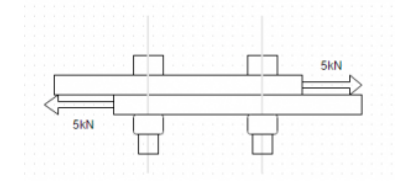

Refer to fig

|

| A. | 8mm |

| B. | 9mm |

| C. | 10mm |

| D. | 11mm |

| Answer» A. 8mm | |

| Explanation: permissible hear stress=0.5 x 400 /4 =50n/mm². p=2 (π xd²/4) x τ or 5000=2 x π x d² x 50/4 or d=7.97mm. | |

| 45. |

8’CW from the vertical. Hence net shear force = √ [5000cos36.8+1250]²+ [5000sin36.8]². |

| A. | 10.74mm |

| B. | 9.23mm |

| C. | 11.54mm |

| D. | 8.68mm |

| Answer» A. 10.74mm | |

| Explanation: the maximum shear force to which any bolt is subjected is 6047.44n. hence 0.5 x 400/3= 4 x 6047.44/πd² or d=10.74mm. | |

| 46. |

Which bolt is under maximum shear stress? |

| A. | 1 |

| B. | 2 |

| C. | 3 |

| D. | all are under equivalent shear stress |

| Answer» C. 3 | |

| Explanation: primary shear force acts equally on the three bolts in the vertically upward direction while the moment is cw along cg so its effect on bolts will be acw. hence secondary shear force acts vertically upward on bolt 3 and vertically downward on bolt 1. | |

| 47. |

Arrange the bolts in order of decreasing shear stresses. |

| A. | 1>2>3 |

| B. | 2>1>3 |

| C. | 3>1>2 |

| D. | 3>2>1 |

| Answer» D. 3>2>1 | |

| Explanation: on bolt 3,primary and secondary shear stress act in same direction, on bolt 2 there is no secondary shear stress and on bolt 1 the two act in opposite direction. | |

| 48. |

Determine the size of the bolts if yield strength of bolt is 400N/mm² and factor of safety is 4. The bolts are equidistant having separated by 60mm and the margin to the left and right is 25mm. Also P=5kN acts at a distance of 200mm from the channel. |

| A. | 14.34mm |

| B. | 13.44mm |

| C. | 15.44mm |

| D. | 12.66mm |

| Answer» B. 13.44mm | |

| Explanation: clearly bolt 3 is under maximum shear stress. net shear stress= primary shear stress + secondary shear stress or τ= (1000+6100) n or 0.5 x 400//4=7100 x | |

| 49. |

A knuckle joint is unsuitable for two rotating shafts, which transmit torque |

| A. | true |

| B. | false |

| Answer» A. true | |

| Explanation: knuckle joint can’t be used for torque transmission. | |

| 50. |

A maximum of how many roads may be connected using a knuckle joint? |

| A. | 2 |

| B. | 3 |

| C. | 4 |

| D. | 5 |

| Answer» B. 3 | |

| Explanation: in rare explanation, two rods with forks and one rod with eye is connected. | |

Done Studing? Take A Test.

Great job completing your study session! Now it's time to put your knowledge to the test. Challenge yourself, see how much you've learned, and identify areas for improvement. Don’t worry, this is all part of the journey to mastery. Ready for the next step? Take a quiz to solidify what you've just studied.